The first ultrafast laser was created in the 1970s. However, their development for various applications continues. This article highlights some recent advances related to ultrafast lasers.

Femtosecond lasers and biological applications

Interaction with living cells

The specific characteristics of femtosecond lasers allow scientists to interact with biological material by modifying cell functions individually. Ultrafast lasers produce short pulses that transfer energy to electrons before they interact with the environment. For instance, an electron can absorb energy from two photons before losing it while interacting with other electrons. This feature helps scientists manipulate living cells.

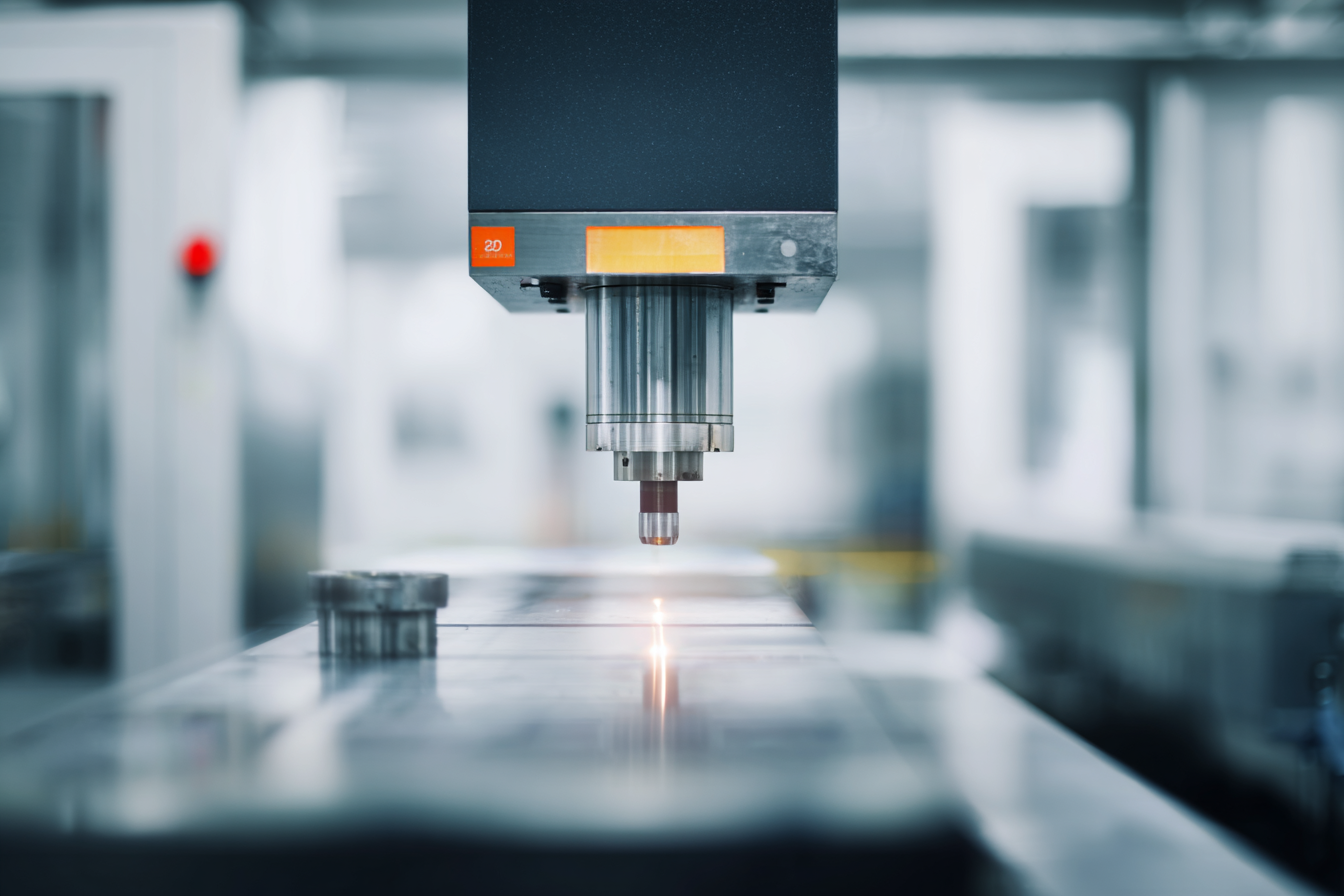

Microfabrication advantages

Ultrafast lasers reduce heat transfer, allowing material ablation without melting. As a result, scientists achieve a clean microfabrication process. By focusing the beam on an area a few microns wide, electrons can be excited with two low-energy photons. This occurs only under high intensity and localized interaction with the material.

Microstructures for biological studies

Scientists have developed ultrafast lasers that create microstructures for biological studies and can modify the behavior of living cells.

Ultrafast lasers in molecular imaging

High-speed X-ray imaging

A research team from China used ultrafast lasers to capture the first molecular films. They fired an intense beam of light at samples to take X-ray photos. Their developed cameras are one billion times faster, making it possible to record the fastest processes, such as chemical reactions.

Molecular movies and global optimization

This invention enables researchers to create the first molecular movies. The team plans to continue optimizing the new fiber laser system and make it accessible to global users.

State-of-the-art ultrafast laser systems

Fiber laser pulses and material analysis

This new fiber laser system, based on an ultrafast laser, represents state-of-the-art fiber laser technology. It produces pulses with identical photons and detects small structural changes in materials. Tests were conducted using the “water window,” a spectral range where photons are absorbed by carbon but not by oxygen. Water is more transparent to X-rays, while elements like carbon strongly interact with them. Coherent ultrafast pulses allowed scientists to capture X-ray images of molecules and atoms.

Implications for science and technology

Both technologies aim to uncover fundamental processes in materials, technology, and living organisms. They will also lead to new discoveries in fiber laser technology.