Laser modules are applied in various industrial fields due to the wide spectrum of produced wavelengths. High-power fiber laser systems are commonly used for welding, marking, cutting, etc. Low-power but more precise fiber lasers are suitable for applications requiring high accuracy, for example, in science and medicine.

This article focuses on two applications of low-power fiber laser modules: laser pumping and optical trapping.

Most Common Advantages of Laser Modules

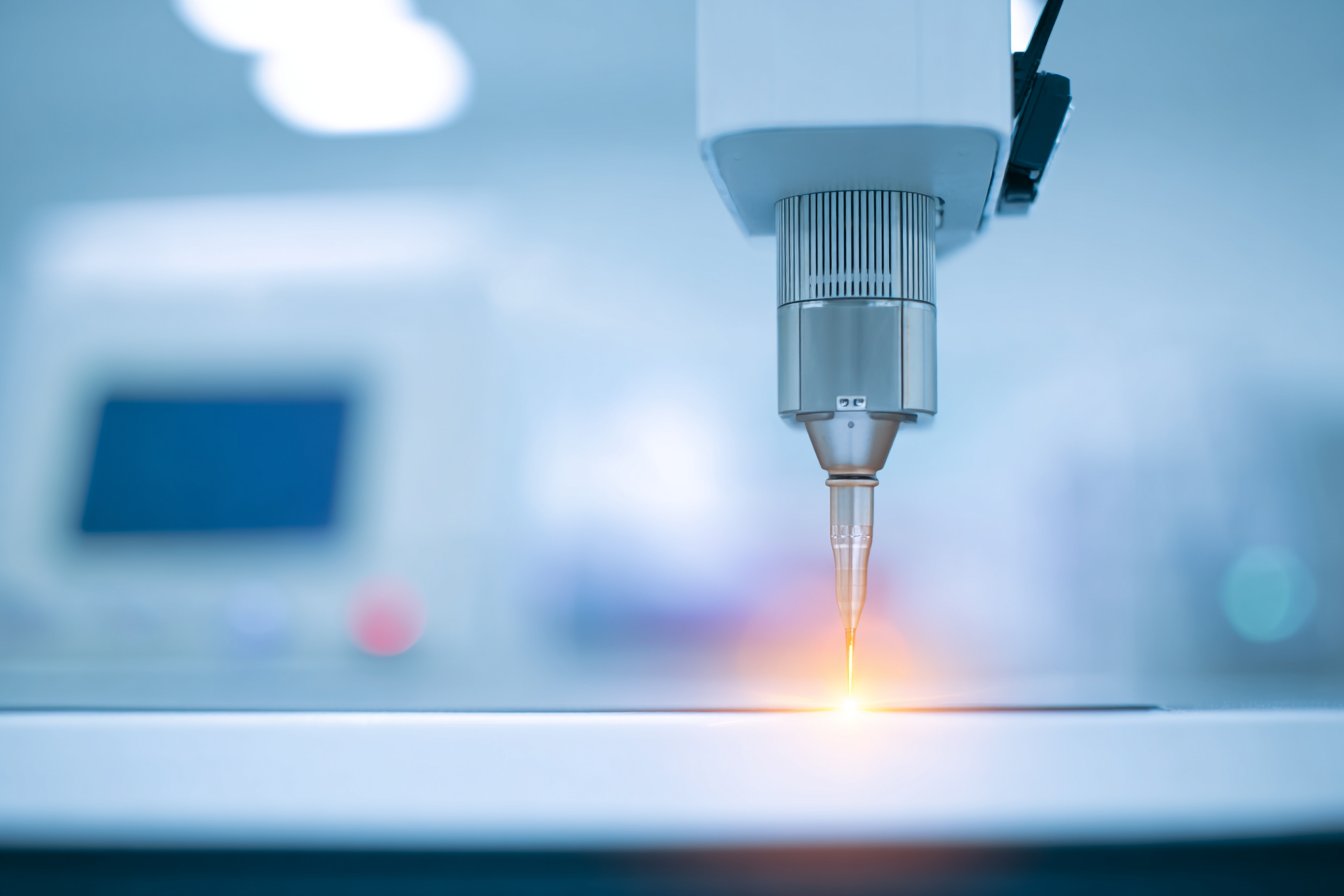

Laser diodes are applied in optical pumping of fiber lasers and DPSS. They are highly effective, robust, and compact. Laser modules provide high peak energy and stable beam quality.

The principle of photon confinement in rare-earth doped fiber gives fiber lasers an advantage: stability. Since a fiber laser generates the beam within the core, it does not require complex or sensitive optical components. Conventional lasers, on the contrary, rely on optical fibers for beam regulation and mirror reflection, which demand frequent precise adjustments. Fiber lasers are less sensitive to vibrations and shocks, maintaining operational stability.

The doped fiber core limits the beam, ensuring higher accuracy and more effective focusing.

Energy efficiency is another strength of fiber lasers. They convert almost all input into the beam, minimizing thermal conversion. This improves thermal protection and reduces degradation.

Most conventional laser sources use water cooling, while fiber lasers use air cooling to dissipate heat. This improves portability and reduces power consumption. Modern air-cooling systems, based on advanced heat dissipation studies, have proven highly effective in mitigating thermal effects.

Fiber laser systems with 1–100 W output power offer a wide range of wavelengths.

Fiber Laser Systems in Optical Pumping

Optical pumping of a laser medium is illumination by an external light source to transfer it to an excited state. Fiber lasers, like all laser systems, require an excitation source to pump energy into the system.

Methods of Optical Pumping

The most common methods of optical pumping include semiconductor lasers (diodes), solid-state, and fiber lasers. Both solid-state and fiber lasers are pumped with diodes.

Pumping can be continuous or pulsed. The difference lies in the delivery method: the pumping source is connected to the fiber core and fused into a double-clad fiber. The cladding material determines whether the absorption band is wide or narrow. Depending on this, conventional or wavelength-stabilized diodes may be applied.

Fiber Laser Modules in Optical Trapping

Optical trapping uses a focused laser beam to hold and manipulate microscopic objects. This technology is widely used in biomedical research.

Applications in Biomedical Research

Optical trapping can study single molecules thanks to its ability to work with nanoparticles. This has greatly advanced research on DNA and proteins.

Most optical trapping systems use laser modules with a 1 μm wavelength, which reduces the risk of biological damage. This range is optimal for aqueous biological specimens with a low absorption coefficient.

Synergy of Optical Pumping and Trapping

Together, optical pumping and optical trapping enable innovative applications in micro- and nanotechnology. Their combined efficiency brings new opportunities to science.