Applications of Holography in Ophthalmology

Holography methods require high-technology laser systems and, just like interpherometery, are often used in ophthalmology. Certain researches have high potential in this sphere: three-dimension image of the eye and its parts, studying optical eye features and measuring internal eye structures with the high resolution.

Imaging Internal Eye Structures

Most of the research today is about creating an image of the internal volume of the eye, and developing an optical scheme to make a wide angle holographic photo. One of the experiments used laser with 632 nm and 589 nm to create a hologram of an eye of animal. Cross-polarization was used to avoid parasite and interfering beams from mirror reflections of an eye and a lens. The images of the blood vessels have been made, however, the main purpose of the holography – three-dimensional image of the objects – hasn’t been achieved. It happened because the resolution wasn’t high enough.

High-technology Laser Systems for Fundus Imaging

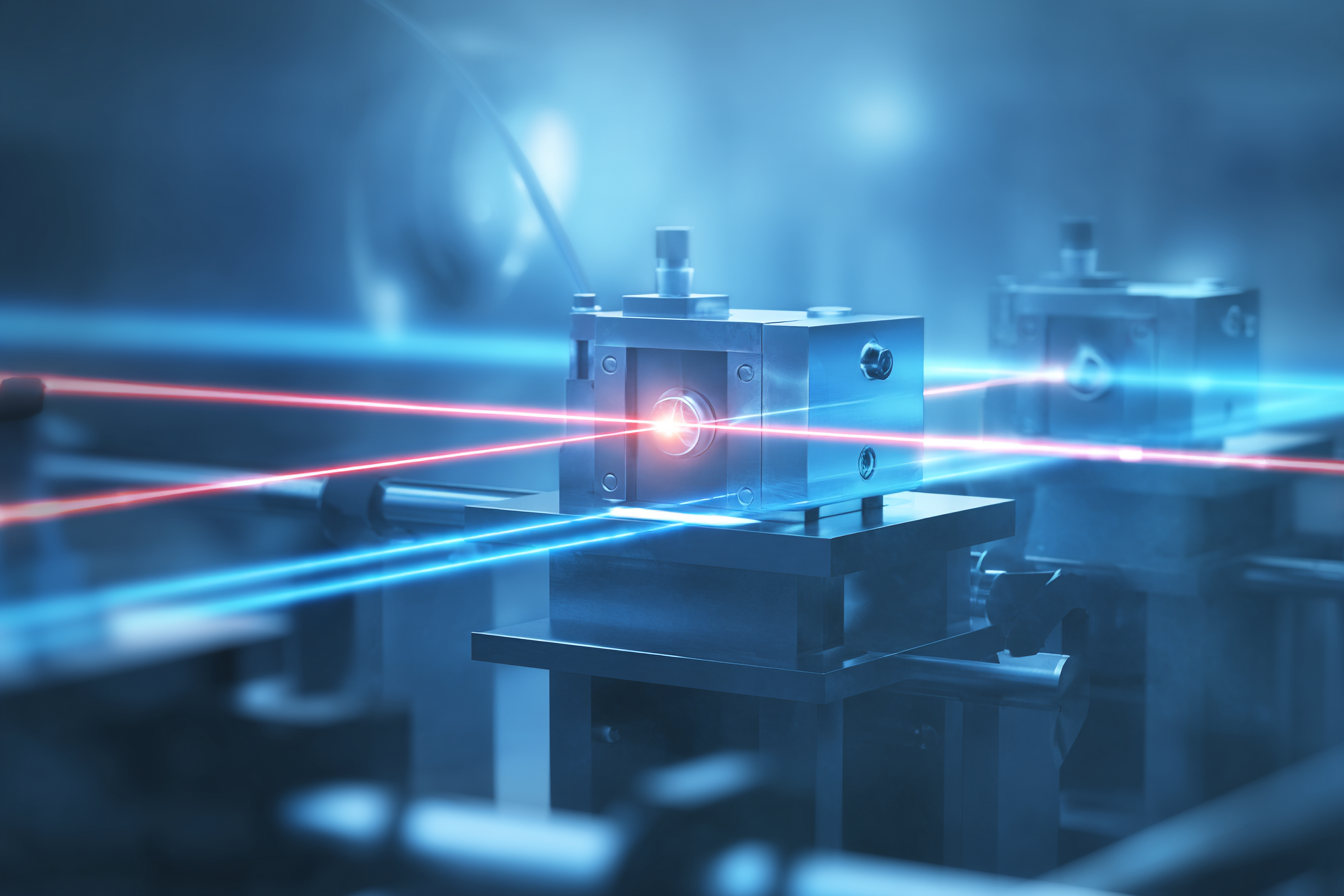

High-technology laser system with double-beam is used to obtain the fundus hologram, the regular fundus camera has its xenon light source replaced with an argon gas laser, and its emission is used to illuminate the eye fundus and create a bearing beam. The studies show that the gas laser holography methods have relatively low resolution and low contract images, which can be explained by the speckle pattern that affects the general image.

Advantages and Methods of Holography

In general, holography with gas laser is useful to localize intraocular foreign body and to study different processes such as tumors, edemas, amotio, etc. Using single-pass holographic registration allows achieving a better quality of three-dimension images, fluorangiography is a primary method, a luminescence colourant is inserted in blood, and it helps to register the images of fundus.

There is no doubt that holography method has a great potential in the area of biomedical diagnostics, in particular, in ophthalmology, however, it presents certain challenges that prevent animal experiments from showing excellent results. Further optimization of high-technology laser systems parameters need to be done.