Since the creation of the first laser modules, specialists have conducted extensive research on the effects of laser radiation on biological tissues. Fiber lasers have contributed to developing various treatment methods for different diseases.

The main advantages of fiber laser modules in medicine

Depending on radiation power, laser modules can be used for heating, cutting, or coagulation of biological tissue.

Key benefits

Advantages of medical instruments with fiber lasers compared to traditional equipment:

- fiber lasers allow non-invasive or minimally invasive cuts;

- high temperatures sterilize wounds, reducing infection risk;

- minimal wound swelling;

- reduced postoperative complications;

- shorter recovery period.

Today, fiber lasers are applied in otorhinolaryngology, vascular disease treatment, cardiac surgery, orthopedics, traumatology, neurosurgery, gynecology, proctology, dentistry, and other fields.

Fiber lasers’ radiation levels and applications

Different effects of fiber laser radiation on biological tissues depend on the wavelength. This is determined by the absorption coefficient, scattering coefficient, and moisture content. Absorption affects penetration depth. Water and hemoglobin are the main absorbers in biological tissues.

Common radiation ranges

Common radiation ranges used in medicine:

- 0.94–0.98 µm radiation provides an optimal balance of cutting and coagulation in surgery;

- 1.06 μm radiation is used for controlled volumetric tissue heating;

- 1.4–1.8 μm wavelength is mainly for water heating to 100 °C and evaporation;

- 1.8–2.1 μm wavelength, like CO2 lasers, offers good cutting, minimal thermal damage, and effective coagulation;

- Lasers with wavelengths >2 μm are widely used. Wavelengths between 2.05–2.3 µm operate in the atmospheric transmission window and are used where eye safety is critical.

Thulium-doped fiber lasers provide 1900–2000 nm wavelengths, matching absorption peaks in biological tissues:

- Fiber lasers up to 10 W are used in cosmetology and dentistry;

- 40 W lasers are applied in gynecology, proctology, and vascular treatments;

- 50–120 W fiber lasers are used in urology for transurethral prostate vaporization.

Features of fiber lasers’ use in medicine

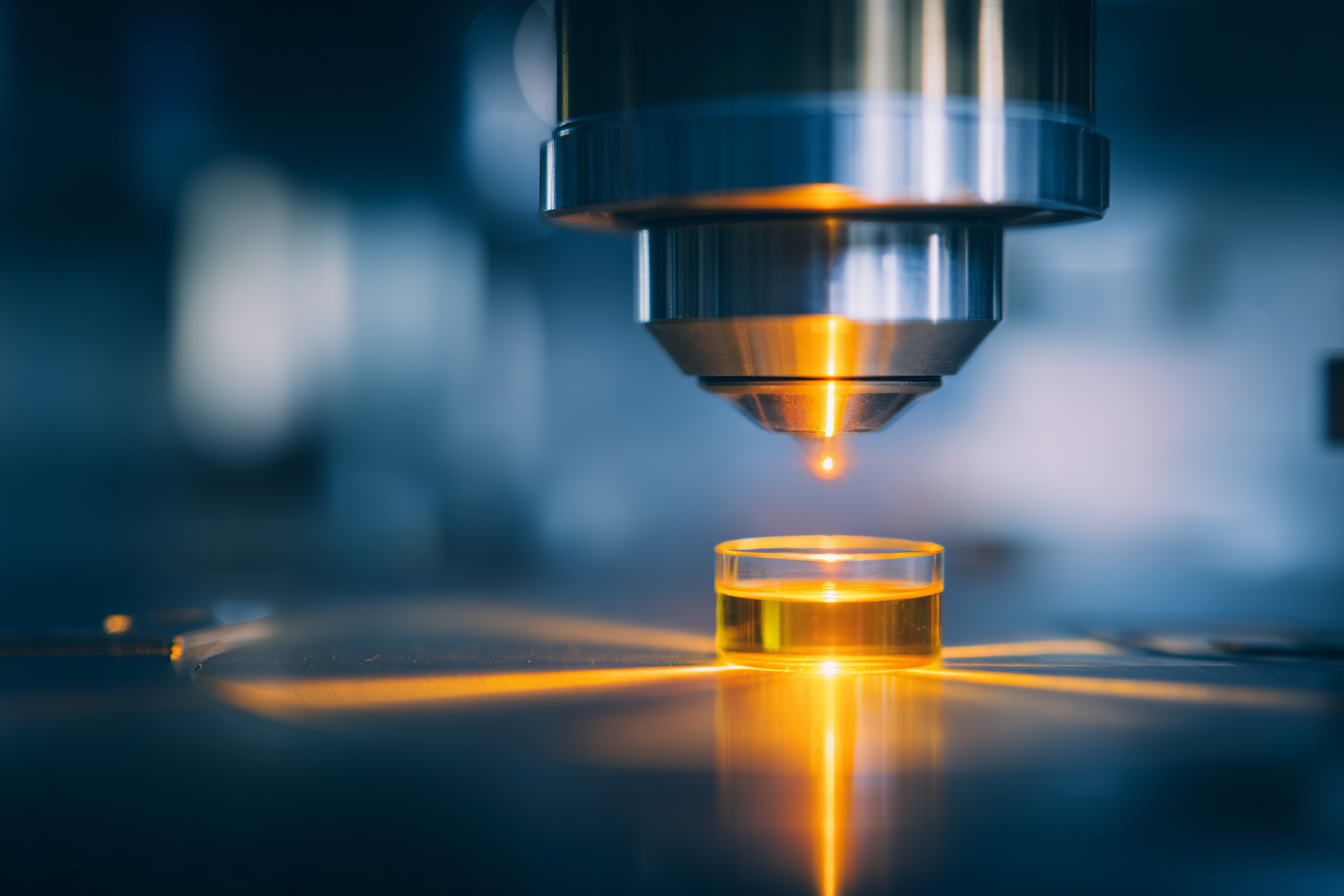

Fiber lasers are used in many technical and scientific fields. They are compact, resistant to vibrations and electromagnetic interference, and can be equipped with various commercially available components.

Individual approach and surgical applications

Each pathology requires an individual approach. Specialists set the appropriate laser modes for each medical field. Fiber lasers help reduce surgical injuries and shorten recovery time. Fiber lasers are important in modern endoscopic surgery and are fully compatible with surgical endoscopes, enabling minimally invasive procedures.

Today, fiber laser modules are widely used in biology and medicine. Future research will focus on laser effects on natural and artificial tissues and on optimizing laser parameters.