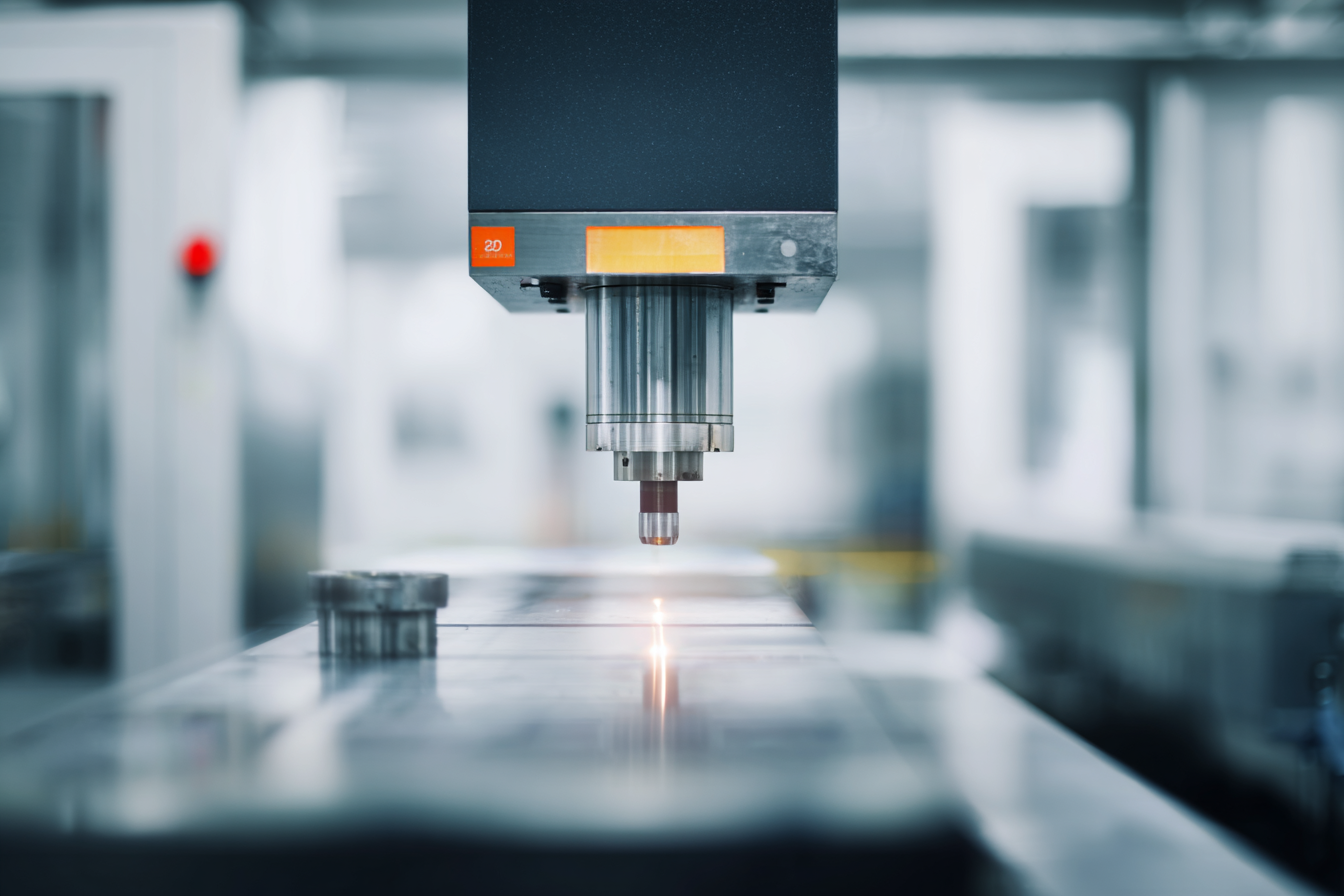

Laser systems for surgical operations

Researchers from the United States, Germany, and Switzerland have presented a comparison of the properties of two types of laser systems applied in urological procedures. The researchers have determined in which cases it is necessary to use each of them and which settings allow for achieving the best result.

Benefits of laser systems in surgery

Laser systems have been used in surgery for more than half a century, and nowadays they are used in urology, for example, during operations for bladder cancer, benign prostatic hyperplasia, and urothelial carcinoma. Laser systems offer several benefits over conventional surgical devices – their application reduces the cases of bleeding and the risk of complications, allowing surgery to be performed minimally invasive (with minimal damage to healthy tissue).

Characteristics of different laser systems

Laser systems are different from each other. The suitability of laser beams for specific types of operations is determined by their wavelength, duration, and strength of the pulse. They choose the degree of absorption and scattering of radiation, which means the speed and depth of dissection, the degree of damage to neighboring tissues, coagulation (irreversible changes in the structure of the protein), and carbonation. Different types of laser systems are suitable for various tasks; however, in recent years Ho:YAG has become popular, ideal for a wide range of operations, due to the high degree of laser beam absorption and pulsed exposure mode.

Development of the thulium fiber laser

Several years ago, specialists jointly developed and studied a new thulium fiber laser. Its laser beam emission is effectively absorbed in the water, which allows for increasing the speed of the operation. At the same time, the pulses of the fiber laser system reach lower peak power, gently dissecting the tissue, rather than tearing it, and they can operate longer, which gives a more uniform distribution of energy and less damage to the tissue.

Modes of operation: Ho:YAG vs. fiber laser

At the same time, Ho:YAG and fiber lasers have already been tested during the operation in two modes: quasi-continuous (a sequence of short pulses of equal power) and super-pulse. Each laser system was tested with different laser beam power settings and different speeds. In each case, the depth of dissection, the depth of coagulation, and the degree of carbonation were evaluated.

The fiber laser system allows deeper dissection of the tissue in a quasi-continuous mode, while the laser effectively coagulates the tissue. The fiber laser system in a quasi-continuous mode makes it possible to effectively dissect tissue and coagulate bleeding vessels, although the degree of tissue carbonization is higher.

The role of fiber lasers in modern surgery

Fiber lasers are one of the biggest and most significant changes in laser surgery in the last 20 years. The capabilities of these devices are actively studied all over the world, and their flexibility allows them to be used in all areas of urology.