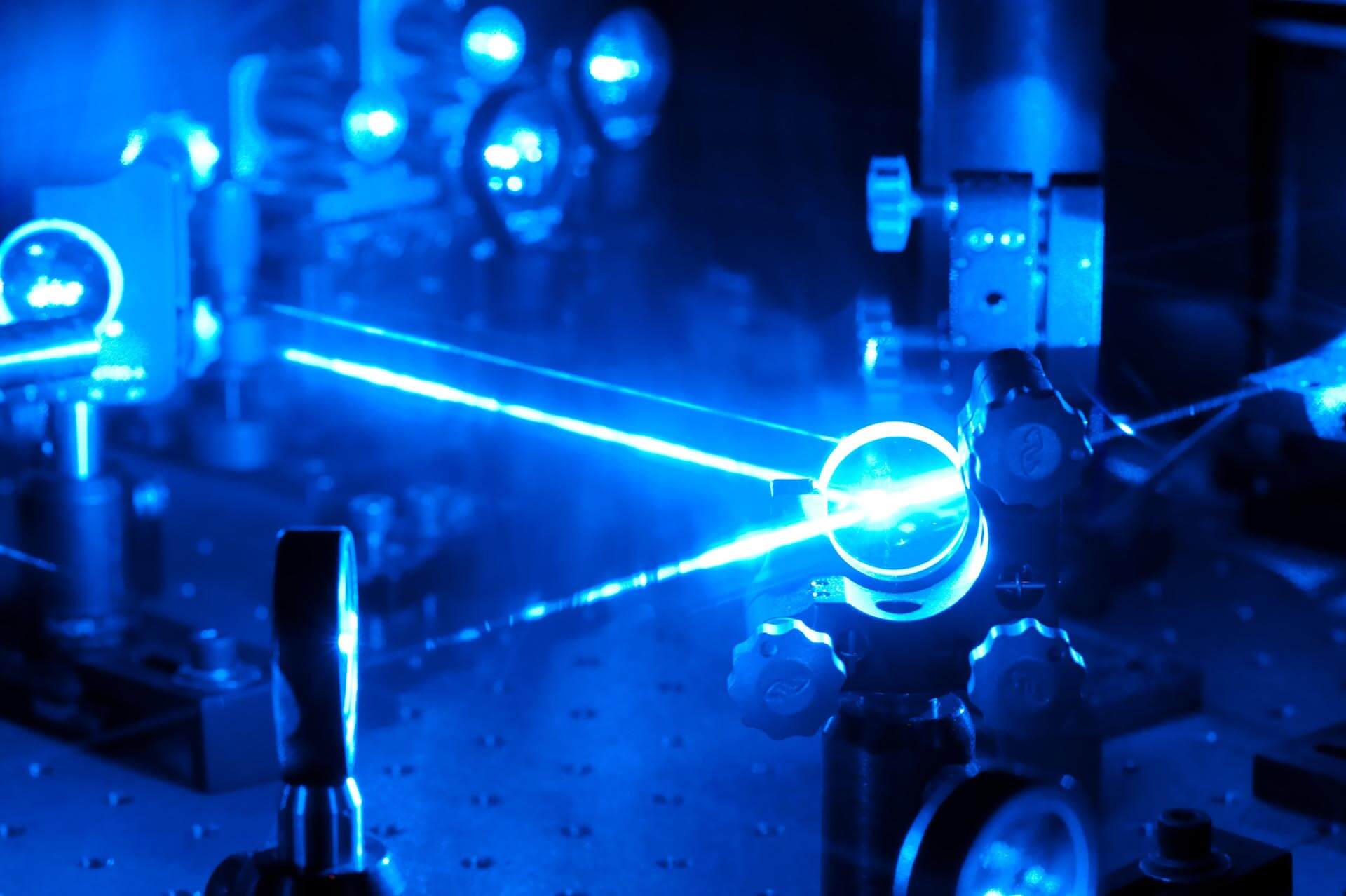

Fiber Lasers For Science

Custom Laser Solutions

Optromix company provides ready-made solutions in a short time and designs special-purpose fiber laser systems of any level of complexity.

Perfect for science

Our specialists are interested in making our fiber laser solutions accessible for all groups of users, particularly for researchers and scientists.

Light & Compact

Optromix specialists are particularly focusing on the small and lightweight fiber laser modules. Thus, our fiber lasers may be required in mobile applications or integrated in various devices.

CW TEM00 Mode Fiber Lasers

SINGLE-FREQUENCY DFB FIBER LASERS

SINGLE-MODE FIBER LASERS

Optromix PME, SME, PMY, and SMY benchtop models are single-mode narrow linewidth 1.5 µm and 1 µm wavelength Erbium or Ytterbium fiber lasers with a linear polarized or an unpolarized output.

The PME/SME/PMY/SMY key parameters are high wavelength stability and thermal wavelength tuning as an option.

DUV FIBER LASERS

Based on the single-frequency green fiber laser, Optromix QSY CW ultraviolet laser system is an excellent replacement of gas lasers and DPSS lasers due to its compact size, air cooling, high reliability, and low power consumption.

Optromix, Inc. is a U.S. Manufacturer Based in Cambridge, MA.

Advanced Fiber Laser Line

- Optromix, Inc. pays special attention to the quality of its fiber laser products and is committed to improving its development and designs.

- Our primary objective is to provide our clients with the best fiber lasers systems and expand all the support they need.

Exstensive Experience in Fiber Lasers

Optromix Company, headquartered in Cambridge, MA, USA, is a manufacturer of fiber lasers, optical fiber sensors, and optical monitoring systems.

We manufacture fiber lasers systems using our own technologies based on the advanced research work and patents of international R&D team.

Optromix develops and manufactures a broad variety of high beam quality Fiber Lasers.

We offer single-mode Erbium lasers and Ytterbium lasers as well as single-frequency fiber lasers (similar to DFB lasers), wavelength tunable fiber lasers systems, and unique DUV fiber laser system.

Optromix offers fiber laser systems in a wide range of wavelengths: 1.5 µm Erbium laser (1532-1585 nm), 1 µm Ytterbium laser (1030-1110 nm), Near-IR fiber laser (770 -790 nm), Green fiber laser (515 – 561 nm), DUV fiber laser (257.5 nm).

Optromix core competency is developing and manufacturing continuous wave single-frequency ultra-narrow linewidth fiber lasers based on the similar to DFB technology. These lasers find wide application in optical sensing systems, atomic cooling, atomic spectroscopy, optical trapping, interferometry, etc.

When manufacturing our fiber laser products we implement unparalleled quality management system with world-class requirements and regulations. Manufacturing processes are high quality and high precision.

Optromix erbium laser, ytterbium laser, and other laser technologies offer a vast range of applications and can be used in different research fields.

Optromix prioritizes the needs of our clients and we are always dedicated to creating unique and innovative technologies.